Thursday, November 05, 2015

Friday, August 21, 2015

Monday, August 17, 2015

Friday, February 20, 2015

Wednesday, February 18, 2015

Tuesday, August 12, 2014

Duckworks Magazine - Chapter 8: Scarfing

Duckworks Magazine - Chapter 8: Scarfing

David Nichols has written a new

book and has graciously consented to

let us post one of the chapters before it comes

out. It will be titled "LAPSTRAKE CANOES: Everything

You Need to Know to Build a Light, Strong, Beautiful

Boat" and will be published by Garth Battista

at Breakaway

Books, the publishers of books by Jim

Michalak and Max

Wawrzyniak.

David Nichols has written a new

book and has graciously consented to

let us post one of the chapters before it comes

out. It will be titled "LAPSTRAKE CANOES: Everything

You Need to Know to Build a Light, Strong, Beautiful

Boat" and will be published by Garth Battista

at Breakaway

Books, the publishers of books by Jim

Michalak and Max

Wawrzyniak.

Friday, July 25, 2014

Thursday, May 29, 2014

New Matter 3D printer

New Matter 3D printer

Customers seeking to enter the field of 3D printing will typically shell out between $500 to $2500. For a less expensive 3D printer, one would have to search for DIY 3D printer kits. The New Matter 3D Printer intends to change this with their MOD-t debut. The MOD-t is based on 3D major design considerations: affordability, easy to use software, and access to 3D designs. - See more at: http://www.3diot.net/new-matter-3d-printer/#sthash.ycheLWTY.dpuf

3D printing artisans use a variety of tools to shape and then fabricate a physical design. From modeling our natural surroundings to engineering a mechanical component, everything begins with imagination, translated to digital canvas, then printed into reality. We’ve compiled a list of 3D modeling and printing tools to help you get started.

Customers seeking to enter the field of 3D printing will typically shell out between $500 to $2500. For a less expensive 3D printer, one would have to search for DIY 3D printer kits. The New Matter 3D Printer intends to change this with their MOD-t debut. The MOD-t is based on 3D major design considerations: affordability, easy to use software, and access to 3D designs. - See more at: http://www.3diot.net/new-matter-3d-printer/#sthash.ycheLWTY.dpuf

3D printing artisans use a variety of tools to shape and then fabricate a physical design. From modeling our natural surroundings to engineering a mechanical component, everything begins with imagination, translated to digital canvas, then printed into reality. We’ve compiled a list of 3D modeling and printing tools to help you get started.

Wednesday, May 28, 2014

Monday, April 21, 2014

Friday, April 04, 2014

Desktop Electronic Cutting Tools, Hobby Users Forum - A Google Group

Desktop Electronic Cutting Tools, Hobby Users Forum - Google Groups

Open discussions topics: Silhouette CAMEO, Cricut Expression Cutting

Machine, Brother ScanNCut, create intricate pieces. This an open group

for discussing, machines, materials and projects

Group allows posting by email: ElectronicCuttingTools@googlegroups.com Language English

Group feeds are available:

15 new messages at a time RSS Atom,

50 new messages at a time RSS Atom

15 new topics at a time RSS Atom,

50 new topics at a time RSS Atom

Anyone can view content.

Anyone can join.

Only members can post.

Open discussions topics: Silhouette CAMEO, Cricut Expression Cutting

Machine, Brother ScanNCut, create intricate pieces. This an open group

for discussing, machines, materials and projects

Group allows posting by email: ElectronicCuttingTools@googlegroups.com Language English

Group feeds are available:

15 new messages at a time RSS Atom,

50 new messages at a time RSS Atom

15 new topics at a time RSS Atom,

50 new topics at a time RSS Atom

Anyone can view content.

Anyone can join.

Only members can post.

Tuesday, April 01, 2014

▶ Ship Model - Armed Virginia Sloop, 1768 - Model Shipways, Preparing For Planking - Part 2 - YouTube

▶ Ship Model - Armed Virginia Sloop, 1768 - Model Shipways, Preparing For Planking - Part 2 - YouTube

https://www.youtube.com/user/modelshipbuilder73/videos

https://www.youtube.com/user/modelshipbuilder73/videos

▶ Model-Making - Making of a Fishing Boat Model - YouTube

▶ Model-Making - Making of a Fishing Boat Model - YouTube

https://www.youtube.com/user/modellismodautore/videos

https://www.youtube.com/user/modellismodautore/videos

▶ Flying Cloud Splicing Hull Planks Ship Model - Steve Priske - YouTube

▶ Flying Cloud Splicing Hull Planks Ship Model - Steve Priske - YouTube

https://www.youtube.com/user/anchorsaweighms/videos

https://www.youtube.com/user/anchorsaweighms/videos

▶ planking - YouTube

▶ planking - YouTube

Vasileios Botis- Maria-Frederica Gregory

https://www.youtube.com/user/MrVasbot/videos

Vasileios Botis- Maria-Frederica Gregory

https://www.youtube.com/user/MrVasbot/videos

▶ Origami Boat Hull Model - First Attempt - YouTube

▶ Origami Boat Hull Model - First Attempt - YouTube

https://www.youtube.com/user/submarineboat/videos

https://www.youtube.com/user/submarineboat/videos

▶ new Bat hull Plank on frame with Martin Baylis triple - YouTube

▶ new Bat hull Plank on frame with Martin Baylis triple - YouTube

https://www.youtube.com/user/DELTA1DSV

https://www.youtube.com/user/DELTA1DSV

▶ HOW TO MAHOGANY PLANK A BRASS MODEL BOAT RUDDER - YouTube

▶ HOW TO MAHOGANY PLANK A BRASS MODEL BOAT RUDDER - YouTube

https://www.youtube.com/user/keithappleton

https://www.youtube.com/user/keithappleton

▶ How to Make Mini Wood Planks Using Micro-Mark #14568 Wood Strip Cutter - YouTube

▶ How to Make Mini Wood Planks Using Micro-Mark #14568 Wood Strip Cutter - YouTube

https://www.youtube.com/user/micromarktools

https://www.youtube.com/user/micromarktools

Monday, March 31, 2014

Tuesday, March 25, 2014

Tuesday, February 25, 2014

Monday, February 24, 2014

Sunday, February 23, 2014

Free 3D Modeling Software, 3D Models, DIY

Autodesk 123D - Free 3D Modeling Software, 3D Models, DIY ...

Top 5 Autodesk Meshmixer 3D Printing Features: Top 5 3D Printing Features in the new Autodesk

http://tinyurl.com/3v8dha8

http://www.123dapp.com/

http://www.123dapp.com/create

Top 5 Autodesk Meshmixer 3D Printing Features: Top 5 3D Printing Features in the new Autodesk

http://tinyurl.com/3v8dha8

http://www.123dapp.com/

http://www.123dapp.com/create

Wednesday, February 12, 2014

to drill and tap wood (bass wood) from RodCarr@carrsails.com via yahoogroups.com

Drill a proper sized pilot hole.

Load it with thin CA.

Tap your thread.

5-40 or larger will work reasonably.

Smaller than that, not so much.

Rod Carr

Monday, January 27, 2014

3D printers and laser cutters

Shifting from Shelves to Snowflakes — The Magazine on Medium — Medium: The subtle odor of melting plastic welcomes you to the Maker Lab at the Harold Washington Public Library in downtown Chicago. Whiteboards covered in scribbles line the bright green walls rather than bookshelves. Librarians aren’t shushing patrons: people talk loudly over the low hum of 3D printers and laser cutters.

Monday, November 11, 2013

RCSails - DIY Sailwinch

RCSails - DIY Sailwinch: DIY Sail Winch

Courtesy of Francis Roussel (FFMN 9635)

franc.roussel@wanadoo.fr

Translated from the French language with the generous help of Bill Young, USA

How to build a Sail Winch from a popular MG995 compatible Servo

The Poor Man's RMG Winch

Courtesy of Francis Roussel (FFMN 9635)

franc.roussel@wanadoo.fr

Translated from the French language with the generous help of Bill Young, USA

How to build a Sail Winch from a popular MG995 compatible Servo

The Poor Man's RMG Winch

Tuesday, October 15, 2013

How to Select a Radio Controlled Model Sailboat: 17 Steps

How to Select a Radio Controlled Model Sailboat: 17 Steps: Scheel 50

Scheel 50

Learn about your model sail boat. Model sail boats often operate with the same sophistication of design as any full-sized yacht. The more sophisticated ones are designed for racing, and the R/C sailors call them "model yachts", to distinguish their more sophisticated models from the "toy" sailboats often sold at toy stores or online

Scheel 50

Learn about your model sail boat. Model sail boats often operate with the same sophistication of design as any full-sized yacht. The more sophisticated ones are designed for racing, and the R/C sailors call them "model yachts", to distinguish their more sophisticated models from the "toy" sailboats often sold at toy stores or online

Tuesday, August 20, 2013

UPS May Have Hit Pay Dirt With 3D Printing - Forbes

UPS May Have Hit Pay Dirt With 3D Printing - Forbes: began offering 3D printing services three weeks ago. There were three pages of customer names and contact information this Sunday. These customers had ordered objects as diverse as robotic arms to custom figurines. “Older guys, especially, travel far to get their vintage parts printed at our store,” he says, adding that he has received customers from places as far as Solana Beach, approximately 15 miles away.

Will UPS Succeed In Popularizing 3D Printing? Rakesh Sharma Rakesh Sharma Contributor

3D Printing Creates Unique Exoskeleton For Broken Bones Jennifer Hicks Jennifer Hicks Contributor

Jones’ store is among the first two UPS stores in the country that is part of the company’s retail test to evaluate 3D printing-as-a-service at its franchises. Restricted to a niche community until now, 3D printing could find a way to the mainstream market, if UPS succeeds with these tests.

Will UPS Succeed In Popularizing 3D Printing? Rakesh Sharma Rakesh Sharma Contributor

3D Printing Creates Unique Exoskeleton For Broken Bones Jennifer Hicks Jennifer Hicks Contributor

Jones’ store is among the first two UPS stores in the country that is part of the company’s retail test to evaluate 3D printing-as-a-service at its franchises. Restricted to a niche community until now, 3D printing could find a way to the mainstream market, if UPS succeeds with these tests.

Friday, August 16, 2013

Thursday, August 08, 2013

UPS 3D Printing manufacturing parts

Will UPS Succeed In Popularizing 3D Printing? - Forbes: many customers interested in 3D printing did not have skills or software to produce 3D files. So, we decided to test the service as a complete package from design to printing.

Remba: It depends on several factors. For example, if a customer brings a design file that is ready to print, then the turnaround time depends on the file printing time. Depending on the physical size and complexity of the object being printed, 3D print jobs can take anything from a few hours for simple projects to more than 24 hours to for large and complex projects. Similarly, we are also testing design services for customers. Our experience is that designing objects also depends on the mode and nature of interaction between customers and the designer. At our first test store in San Diego, the designer works with customers over phone, video conference,

Remba: It depends on several factors. For example, if a customer brings a design file that is ready to print, then the turnaround time depends on the file printing time. Depending on the physical size and complexity of the object being printed, 3D print jobs can take anything from a few hours for simple projects to more than 24 hours to for large and complex projects. Similarly, we are also testing design services for customers. Our experience is that designing objects also depends on the mode and nature of interaction between customers and the designer. At our first test store in San Diego, the designer works with customers over phone, video conference,

Saturday, April 25, 2009

Materials for spars (from 1995 discussion)

[quote]

Date: Wed, 8 Feb 1995 09:32:51 -1000 From: tanaka_be@swam1.enet.dec.com (Bert Tanaka) Message-Id: <9502081930.AA09897@mts-gw.pa.dec.com> Organization: Harvard University Office of Information Technology Subject: New Product - Improved SkyShark 2P rod

I got a set of the new 2P spars from SkyShark and tested them in my Legend IQ ultralight that normally uses the 3P spars. This is a nice 8 gram rod. The old 2P was the same diameter as the 3P, 5P and 7P, which made it convenient because it was interchangeable with the same fittings that are used on the other rods. Although it had a pretty good stiffness to weight ratio, it was also a bit fragile for the heavy use and harsh flying that I like to do. I've never used them because I could break them so easily.

This new 2P is made with a smaller diameter. A concept Erez says that was suggested by David Lord. I believe he used the diameter spec Dave suggested when the new mandrel was selected. Otherwise, it appears to have all the same characteristics of the old rod, except that it is much, much tougher.

I've been flying with it for a while now and have been doing a lot of ground rolls, tip stabs, coins, cartwheels, and hard snap stalls (basically, I've been trying to break them!). Ground work and hard snapping maneuvers will weaken a rod but so far, this new 2P has held up wonderfully. This one is probably tough enough to accept a set of Power-Tite connectors which help to stiffen up the frames made of light weight spars. At any rate, it has proving to be a very durable performer for me.

Good Winds, Bert

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

Date: Thu, 9 Feb 1995 12:19:06 -1000 From: bwg001@carina.unm.edu (Brian W. Gordon) Message-Id: <3he4cq$o30@lynx.unm.edu> Organization: University of New Mexico, Albuquerque Subject: Re: New Product - Improved SkyShark 2P rod

Bert Tanaka (tanaka_be@swam1.enet.dec.com) wrote: : I got a set of the new 2P spars from SkyShark and tested them in my : Legend IQ ultralight that normally uses the 3P spars. This is a nice : 8 gram rod. The old 2P was the same diameter as the 3P, 5P and 7P, which : made it convenient because it was interchangeable with the same fittings : that are used on the other rods. Although it had a pretty good stiffness : to weight ratio, it was also a bit fragile for the heavy use and harsh : flying that I like to do. I've never used them because I could break them : so easily.

: This new 2P is made with a smaller diameter. A concept Erez says that was : suggested by David Lord. I believe he used the diameter spec Dave suggested : when the new mandrel was selected. Otherwise, it appears to have all the same : characteristics of the old rod, except that it is much, much tougher.

: I've been flying with it for a while now and have been doing a lot : of ground rolls, tip stabs, coins, cartwheels, and hard snap stalls : (basically, I've been trying to break them!). Ground work and hard : snapping maneuvers will weaken a rod but so far, this new 2P has held : up wonderfully. This one is probably tough enough to accept a set of : Power-Tite connectors which help to stiffen up the frames made of : light weight spars. At any rate, it has proving to be a very durable : performer for me.

: Good Winds, : Bert

Thanks for the great info Bert! How do you think these spars will hold up (in terms of toughness) to other SUL spars like the G-Force?

Keith Kidder

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

From: Date: Fri, 17 Feb 1995 01:44:26 -1000 From: mainwari@k12.oit.umass.edu(Dave Mainwaring (Northeast Resources))) Message-Id: <1995Feb17.114426.12799@k12.ucs.umass.edu> Organization: University of Massachusetts/Amherst K-12 Information System Reply-To: mainwari@k12.oit.umass.edu(Dave Mainwaring (Northeast Resources))) Subject: Re: New Product - Improved SkyShark 2P rod

In a previous article, bwg001@carina.unm.edu (Brian W. Gordon) says:

/>Bert Tanaka (tanaka_be@swam1.enet.dec.com) wrote: />: I got a set of the new 2P spars from SkyShark and tested them in my />: Legend IQ ultralight that normally uses the 3P spars. This is a nice />: 8 gram rod. The old 2P was the same diameter as the 3P, 5P and 7P, which />: made it convenient because it was interchangeable with the same fittings />: that are used on the other rods. Although it had a pretty good stiffness />: to weight ratio, it was also a bit fragile for the heavy use and harsh />: flying that I like to do. I've never used them because I could break them />: so easily. />

any suggestions on locating sources for spars, I,m in the Boston MA area. --Dave Mainwaring Northeast Resources (617) 455 9920 FAX 617 449 1826

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

Date: Fri, 17 Feb 1995 08:15:23 -1000 From: sasaki@netope.harvard.edu (Marty Sasaki) Message-Id: <3i2p3r$4u5@netope.harvard.edu> Organization: Harvard University Subject: Re: New Product - Improved SkyShark 2P rod

In article <1995Feb17.114426.12799@k12.ucs.umass.edu>, mainwari@k12.ucs.umass.edu (Dave Mainwaring (Northeast Resources)) writes: |>any suggestions on locating sources for spars, I,m in the Boston MA area.

Don McCasland at Kites of Boston has a pretty good stock of spars and can order anything that he doesn't have.

I can provide small numbers of spars for repairs and such. I don't really do retail, however, but am happy to help out if you need something on the field and I have it with me.

I highly recommend Tom Marvin at Hang-em High Fabrics in Richmond VA. Tom has all sorts of spars and fittings along with Icarex and regular ripstop nylon.

Another good source of spars is the High Fly Kite Co in New Jersey. Fran Gramkowski has lots of experience with all sorts of kite spars.

--Marty Sasaki Harvard University Sasaki Kite Fabrications sasaki@harvard.edu Network Services Division 90 Melrose Street 617-496-4320 10 Ware Street Arlington, MA 02174 Cambridge, MA 02138-4002 phone/fax: 617-646-1925

[/quote]

Date: Wed, 8 Feb 1995 09:32:51 -1000 From: tanaka_be@swam1.enet.dec.com (Bert Tanaka) Message-Id: <9502081930.AA09897@mts-gw.pa.dec.com> Organization: Harvard University Office of Information Technology Subject: New Product - Improved SkyShark 2P rod

I got a set of the new 2P spars from SkyShark and tested them in my Legend IQ ultralight that normally uses the 3P spars. This is a nice 8 gram rod. The old 2P was the same diameter as the 3P, 5P and 7P, which made it convenient because it was interchangeable with the same fittings that are used on the other rods. Although it had a pretty good stiffness to weight ratio, it was also a bit fragile for the heavy use and harsh flying that I like to do. I've never used them because I could break them so easily.

This new 2P is made with a smaller diameter. A concept Erez says that was suggested by David Lord. I believe he used the diameter spec Dave suggested when the new mandrel was selected. Otherwise, it appears to have all the same characteristics of the old rod, except that it is much, much tougher.

I've been flying with it for a while now and have been doing a lot of ground rolls, tip stabs, coins, cartwheels, and hard snap stalls (basically, I've been trying to break them!). Ground work and hard snapping maneuvers will weaken a rod but so far, this new 2P has held up wonderfully. This one is probably tough enough to accept a set of Power-Tite connectors which help to stiffen up the frames made of light weight spars. At any rate, it has proving to be a very durable performer for me.

Good Winds, Bert

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

Date: Thu, 9 Feb 1995 12:19:06 -1000 From: bwg001@carina.unm.edu (Brian W. Gordon) Message-Id: <3he4cq$o30@lynx.unm.edu> Organization: University of New Mexico, Albuquerque Subject: Re: New Product - Improved SkyShark 2P rod

Bert Tanaka (tanaka_be@swam1.enet.dec.com) wrote: : I got a set of the new 2P spars from SkyShark and tested them in my : Legend IQ ultralight that normally uses the 3P spars. This is a nice : 8 gram rod. The old 2P was the same diameter as the 3P, 5P and 7P, which : made it convenient because it was interchangeable with the same fittings : that are used on the other rods. Although it had a pretty good stiffness : to weight ratio, it was also a bit fragile for the heavy use and harsh : flying that I like to do. I've never used them because I could break them : so easily.

: This new 2P is made with a smaller diameter. A concept Erez says that was : suggested by David Lord. I believe he used the diameter spec Dave suggested : when the new mandrel was selected. Otherwise, it appears to have all the same : characteristics of the old rod, except that it is much, much tougher.

: I've been flying with it for a while now and have been doing a lot : of ground rolls, tip stabs, coins, cartwheels, and hard snap stalls : (basically, I've been trying to break them!). Ground work and hard : snapping maneuvers will weaken a rod but so far, this new 2P has held : up wonderfully. This one is probably tough enough to accept a set of : Power-Tite connectors which help to stiffen up the frames made of : light weight spars. At any rate, it has proving to be a very durable : performer for me.

: Good Winds, : Bert

Thanks for the great info Bert! How do you think these spars will hold up (in terms of toughness) to other SUL spars like the G-Force?

Keith Kidder

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

From: Date: Fri, 17 Feb 1995 01:44:26 -1000 From: mainwari@k12.oit.umass.edu(Dave Mainwaring (Northeast Resources))) Message-Id: <1995Feb17.114426.12799@k12.ucs.umass.edu> Organization: University of Massachusetts/Amherst K-12 Information System Reply-To: mainwari@k12.oit.umass.edu(Dave Mainwaring (Northeast Resources))) Subject: Re: New Product - Improved SkyShark 2P rod

In a previous article, bwg001@carina.unm.edu (Brian W. Gordon) says:

/>Bert Tanaka (tanaka_be@swam1.enet.dec.com) wrote: />: I got a set of the new 2P spars from SkyShark and tested them in my />: Legend IQ ultralight that normally uses the 3P spars. This is a nice />: 8 gram rod. The old 2P was the same diameter as the 3P, 5P and 7P, which />: made it convenient because it was interchangeable with the same fittings />: that are used on the other rods. Although it had a pretty good stiffness />: to weight ratio, it was also a bit fragile for the heavy use and harsh />: flying that I like to do. I've never used them because I could break them />: so easily. />

any suggestions on locating sources for spars, I,m in the Boston MA area. --Dave Mainwaring Northeast Resources (617) 455 9920 FAX 617 449 1826

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

Date: Fri, 17 Feb 1995 08:15:23 -1000 From: sasaki@netope.harvard.edu (Marty Sasaki) Message-Id: <3i2p3r$4u5@netope.harvard.edu> Organization: Harvard University Subject: Re: New Product - Improved SkyShark 2P rod

In article <1995Feb17.114426.12799@k12.ucs.umass.edu>, mainwari@k12.ucs.umass.edu (Dave Mainwaring (Northeast Resources)) writes: |>any suggestions on locating sources for spars, I,m in the Boston MA area.

Don McCasland at Kites of Boston has a pretty good stock of spars and can order anything that he doesn't have.

I can provide small numbers of spars for repairs and such. I don't really do retail, however, but am happy to help out if you need something on the field and I have it with me.

I highly recommend Tom Marvin at Hang-em High Fabrics in Richmond VA. Tom has all sorts of spars and fittings along with Icarex and regular ripstop nylon.

Another good source of spars is the High Fly Kite Co in New Jersey. Fran Gramkowski has lots of experience with all sorts of kite spars.

--Marty Sasaki Harvard University Sasaki Kite Fabrications sasaki@harvard.edu Network Services Division 90 Melrose Street 617-496-4320 10 Ware Street Arlington, MA 02174 Cambridge, MA 02138-4002 phone/fax: 617-646-1925

[/quote]

Labels:

electric power,

model boat,

model yacht,

plastic,

R/C,

racing models.Star45,

radio control,

RC,

scale model,

scratch build,

shipmodel,

Star 45,

steam ships,

tall ships,

tow boat,

tug,

wooden

Wednesday, March 18, 2009

Gorilla's two-part epoxy

Product Detail

Gorilla Epoxy

Gorilla Epoxy is taking epoxy to the next level, the Gorilla Tough level. Gorilla's two-part epoxy is an Impact-Tough Formula, providing high impact resistance and strength to handle the toughest projects. Plus, it's fast! Gorilla Epoxy sets in 5 minutes and can be handled in 90 minutes.

Gorilla Epoxy's gap-filling capabilities and all purpose formula easily bond steel, wood, aluminum, ceramic and much more.

*

Impact-Tough Formula – hybrid technology improves overall adhesion strength and flexibility.

*

Gap Filling – fills voids and bonds uneven and vertical surfaces.

*

5-Minute Set – plenty of repositioning time for the perfect fit.

*

Water Resistant – withstands moderate exposure to water.

*

Easy-to-Use Reusable Syringe – separate barrels of resin and hardener keep epoxy from hardening, plus syringe dispenses evenly and includes a cap for multiple uses.

*

Solvent Resistant – will not break down from exposure to common solvents.

*

Low VOC and Non-toxic Once Cured – safe for everyday handling.

Saturday, March 14, 2009

Revolutionary push rod connector system

D&E KLI-Cons™ - Caswell Inc.

Revolutionary push rod connector system from the Wizard of Model Making –

David Merriman!

Related Products

* Gato Model

* More Models

Kli-Cons

No more fiddling with set screws, stripped threads, looking for Allen keys. Connect your push-rods in a split second!

Earth magnets grip each section of the push-rod together to withstand the most rigorous workout.

Each KLI-Cons™ magnet set comes with a special threaded brass connector, which you solder to the end of your push-rod.

Kli-Cons

The magnets are threaded onto the new pushrod end, fine tuning by threading up or down. Approximately ½” adjustment is possible.

KLI-Cons™ come in pairs, north and south magnets. Place in different directions to ensure you do not connect the wrong push rod; the wrong magnet will repel the rod.

Friday, January 30, 2009

Add an airhorn to your model

How to Make a Medicine Bottle Air Horn

from wikiHow - The How to Manual That You Can Edit

An air horn brought from the store will only last as long as the compressed air inside the can does, but with a few household items, you can easily make your own air horn that will last quite a long time!

Steps

- Using a heated screwdriver will make it easier.Poke a hole in the cap, side, and bottom of the medicine bottle. Size does not matter, except for the hole on the bottom, which should be large enough for a drinking straw to fit snugly into.

- Take the cap off the bottle. Cut a piece of a balloon and stretch it over the top of the bottle. Secure the balloon with a rubber band. Replace the cap on the bottle.

- Cut another piece of a balloon and stretch it over the bottom of the bottle. Secure it with a rubber band.

- Poke the straw through the hole on the bottom. It might be helpful to first poke a hole in the balloon.

- To use, blow into the hole on the side.

Video

Tips

- Use a heated screwdriver to make poking holes in the bottle easier.

- If it's not working, try moving the straw up and down.

- The straw should be longer than the bottle itself.

- The larger the straw (in circumference), the louder the sound will be.

- Making the hole on the side larger will make it less of a strain on your cheeks to blow into it.

Warnings

- Do not use this air horn near anyone's ears; it could cause hearing damage.

- If using a heated screwdriver, exert caution not to burn yourself or to breathe in the fumes of the plastic.

- Exercise appropriate caution when using edged tools such as scissors.

Things You'll Need

- Medicine bottle

- Scissors

- Balloons

- Drinking straw

- Rubber bands

Printer Friendly Version

Article provided by wikiHow, a wiki how-to manual. Please edit this article and find author credits at the original wikiHow article on How to Make a Medicine Bottle Air Horn. All content on wikiHow can be shared under a Creative Commons license.

Tuesday, January 27, 2009

Brick In The Yard Mold Supply - YouTube

Brick In The Yard Mold Supply - YouTube

It is our goal to provide you with the best materials for your project. BITY Mold Supply is proud to offer trusted brands such as Polytek RTV rubbers & plastics, Accu-Cast Alginates, Sculpt Nouveau Patinas & Metal Coatings, Premeire Products Inc. (Skin Illustrator Makeup & Telesis adhesives and removers), Chavant Clays, Monster Clay, Protolina Clay, and Hot Wire Foam Factory tools. Our products are used extensively for ornamental plaster reproduction, art bronze casting, special makeup effects, prototyping, product development, displays, concrete casting, and cast stone production. Advances in silicone formulation have resulted in several easy to use 1:1 mix ratio silicones, as well as many easy to use polyurethane mold rubber products. BITY also is proud to offer the most popular special effects material around, PlatSil Gel-10 and PlatSil Gel-00. Learn more about Gel-10 and our other products on our YouTube channel. Call us today to find out which material is best for your mold making or casting application.

Welcome to our youtube page! Brick In The Yard Mold Supply was started in 2004. We opened our shop to bring a full selection of molding, casting, and SPFX supplies into the Dallas/Ft. Worth area as well as the technical support to go with it. In 2006 we began using youtube to offer visual answers to common customer questions. Our youtube page is now over 7 years old and has become a virtual library for the mold making and SPFX community.

We keep our page current with video tutorials detailing all aspects of mold making and casting as well as special effects techniques. Visiting the Dallas area? stop by our physical store or shop online at www.brickintheyard.com

It is our goal to provide you with the best materials for your project. BITY Mold Supply is proud to offer trusted brands such as Polytek RTV rubbers & plastics, Accu-Cast Alginates, Sculpt Nouveau Patinas & Metal Coatings, Premeire Products Inc. (Skin Illustrator Makeup & Telesis adhesives and removers), Chavant Clays, Monster Clay, Protolina Clay, and Hot Wire Foam Factory tools. Our products are used extensively for ornamental plaster reproduction, art bronze casting, special makeup effects, prototyping, product development, displays, concrete casting, and cast stone production. Advances in silicone formulation have resulted in several easy to use 1:1 mix ratio silicones, as well as many easy to use polyurethane mold rubber products. BITY also is proud to offer the most popular special effects material around, PlatSil Gel-10 and PlatSil Gel-00. Learn more about Gel-10 and our other products on our YouTube channel. Call us today to find out which material is best for your mold making or casting application.

Welcome to our youtube page! Brick In The Yard Mold Supply was started in 2004. We opened our shop to bring a full selection of molding, casting, and SPFX supplies into the Dallas/Ft. Worth area as well as the technical support to go with it. In 2006 we began using youtube to offer visual answers to common customer questions. Our youtube page is now over 7 years old and has become a virtual library for the mold making and SPFX community.

We keep our page current with video tutorials detailing all aspects of mold making and casting as well as special effects techniques. Visiting the Dallas area? stop by our physical store or shop online at www.brickintheyard.com

Monday, January 26, 2009

very good figure making class

myLargescale.com - Articles - All About Your Garden Railroad & G Scale Trains

myLargescale.com Articles

Modeling Passenger Operations

Chapter I Chapter II Chapter III Chapter IV

Figure Making Class

Chapter I Chapter II Chapter III

Live Steam Class

Chapter I Chapter II Chapter III Chapter IV

from RCGroups forum:

If you go to my large scale, a large scale model railroad site and look in their articles file ( http://archive.mylargescale.com/articles/articles/

) you will find a very good figure making class where the author does

use the aluminum armature and goes in depth on the figure making

process with Sculpey.

Andre

Portland Oregon

Wednesday, January 07, 2009

Model Jonesport Lobster Boat Lines circa 1930-1940

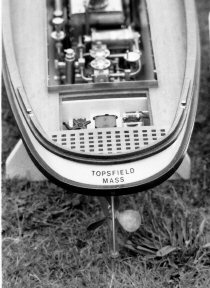

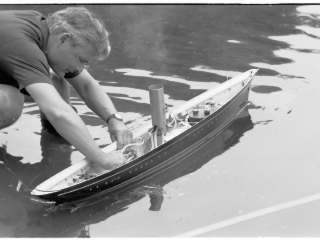

Three of Dave Mainwaring's Jonesport lobster boat display models, plank on rib, early construction stages. One in the background is 32+ inch and two hulls in foreground are 17 1/2 inch. Future models will be built with transoms installed with the planking. They were built over male molds.

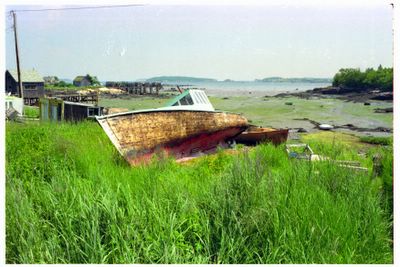

There are abandoned vintage Jonesport style hulls scattered on the shores. Driving through the area from Corea to Damariscotta, Maine you will sold wooden lobster boats passing away in driveways and fields. You will find some of these boats advertised as 1940's lobster boat available free on Ebay. You will also discover as many cabin and deck arrangements as there a hulls. I have photographed many of boats riding at anchor so model builders can see one t use a guide. http://fishingboats.blogspot.com/

Dave M.

In my search for early Jonesport lobster boats I surface a picture of the bone yard in Jonesport Maine.

Labels:

Jonesport,

lines,

Lobster Boat,

mainwaring,

model boat

Subscribe to:

Posts (Atom)